-40%

HyperREZ UV Low Temp 40°F High Build Epoxy Concrete Floor Coating | 100% Solids

$ 149.7

- Description

- Size Guide

Description

HyperREZ UV Low Temp 40°F High Build Epoxy Concrete Floor Coating | 100% SolidsHyperREZ UV Low Temp High Build Epoxy

HyperRez UV is a 100% solids, 2 component epoxy that is extremely hard wearing, high gloss, with excellent UV resistance as well as chemical and impact resistance. Use HyperRez UV to install beautiful, high gloss, seamless, easy to clean, and durable floor coatings. It's ideal for wherever a durable, high build, UV and protective coating is required.

Recommended for residential, commercial and industrial applications. HyperRez UV has no solvent odors and therefore can be used in occupied area<

HyperREZ UV Can Be Applied In Cold Weather Down To 40F and can be applied up 32 mils per coat (50 sq'/gallon) HyperREZ in addition to the normal concrete flooring application can also used on wood floors after an initial coat (acts as flexible membrane) of

HyperFLEX Clear Epoxy

at 90-94 sq'/gallon. Can also be used on wood and concrete countertops with proper preparation.

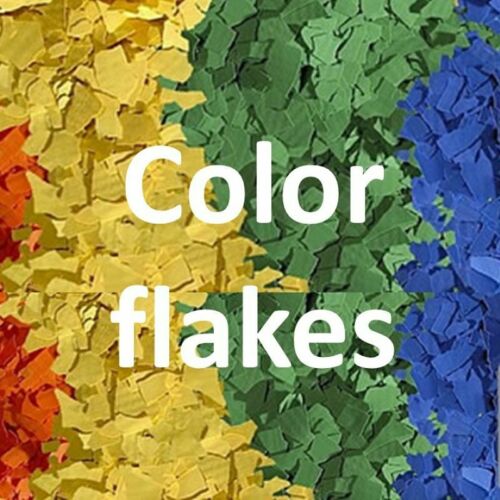

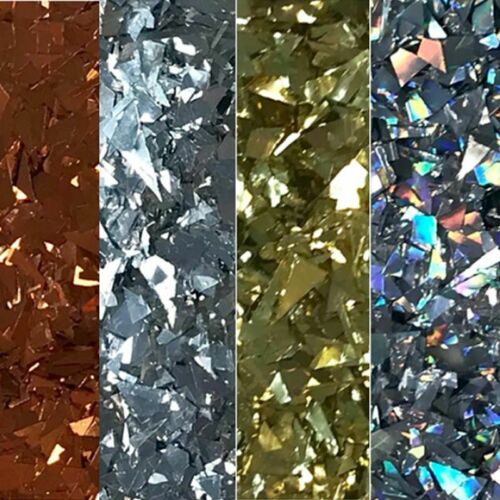

HyperREZ comes in clear or can be tinted with one of

14 Pigmented Colors

(pigment sold separately by the quart).

HyperREZ UV is sold in 1.5 quart, 3 gallon and 15 gallon kits of clear product. Pigmented kits sold separately include 1 pint of pigment, using 3-11 oz. per blended gallon. Pre-pigmented HyperREZ UV available by special order with purchase of 60 gallons or more. HyperREZ UV is also available in a faster setting version for even quicker back in-service times. Apply HyperREZ UV as a base coat at between 10 mils (160 sq/gal)- 16 mils (100 sq'/gal) most applications up to 32 mils (50 sq'/gal) for high build systems.

PRIMER:

None required. Use HyperREZ as primer with black pigment for metallic systems.

TOPCOAT:

Can apply clear coat of urethane or polysapartic coating including

Aspartic 85

or

Aspartic 100

.

Where is HyperREZ Low Temp High Build Epoxy used?

Concrete floors

Wood floors after initial application of HyperFLEX Epoxy

Garage floors

Warehouse, manufacturing and commercial office floors

Kitchens

Projects with colder temperatures

Wood and concrete countertop projects

Why HyperREZ UV Low Temp High Build Epoxy?

Tough, durable epoxy floor coating

Cold temperature application down to 40F

Good chemical and abrasion resistance

High Build Applications up to 32 mils/coat (50 sq'/gal)

UV Resistant

Beautiful high gloss appearance

Designed for high traffic and industrial areas

High solids 100%

Available in clear & 14 colors! (Pigment sold separately)

Beautiful Colors To Enhance Your Flooring Projects. Our Epoxy Pigment Is Sold In Quarts. Easy To Use, Just Pour And Blend with the HyperREZ UV Epoxy. Add 6-7 Oz Per Mixed Gallon Of Pigment, Depending On Desired Color. For A More Rich, Deeper Color, Add Up T0 10 Oz Of Pigment Per Mixed Gallon Of Epoxy. Each 32 Oz Quart Colors 3-5 Gallons Of Floorguard Products Epoxy. Adhesion350 psi @elcometer (concrete failure, no delamination

SPECIFICATIONS

Solids

By Weight 100% By Volume 100%

VOC

<0 g/L

Colors

Clear + 14 colors. See color chart. Pigment sold separately. Can buy pre-pigmented special order for 60 gallons or more

Recommended Film Thickness

10 - 16 mils . Can apply up to 32 mils per coat (50 sq'/gallon)

Coverage per Gallon

100-160 sq'/gal. Can apply as low as 50 sq'/gallon (32 mils) per coat

Packaging

3 gallon kit, 15 gallon kit

Mix Ratio

2:1 by volume (3 gal kit = 2 gal part A & 1 gal part B)

Self Life

12 months in unopened container

Finish

High gloss 60-90 at 60 degrees

Abrasion Resistance

Taber abrasion CS-17 calibrase wheel with 1000g total load & 500 cycles= 36 mg loss

Adhesion

350 psi @elcometer (concrete failure, no delamination)

Viscosity

700 - 1,000 centipose typical

Impact

Gardner Impact, direct & reverse= 50 in/.lb. (passed)

Flexural Strength

7,500 psi @ASTM D790

Compressive Strength

11,200 psi @ASTM D695

Tensile Strength

7,100 psi @ASTM D638

Hardness

Shore D=81

CURE SCHEDULE

Pot Life

40-45 minutes (at 70F - 1-1/2 gal)

Tack free (dry to touch)

12-16 hours

Recoat or topcoat

12 hours minimum

Light foot traffic

24 hours

Full cure (heavy traffic)

5 days

APPLICATION TEMPERATURE:

45-90 degrees F with relative humidity below 85%

CHEMICAL RESISTANCE

RATING

Acetic acid 5%

L

Xylene

R

Mek

L

Gasoline

R

Urea

R

skydrol

R

Ethyl Gylcol

R

50% sodium hydroxide

R

20% sulfuric acid

R

Bleach

L

15% Hydrochloric Acid

R

10% Nitric Acid

R

Rating key: - R recommended for continous service L - Limited recommendation, occasional spills

MIXING AND APPLICATION INSTRUCTIONS

PRODUCT STORAGE

: Product must be stored in an area that will bring the product to room temperature prior to using. Continuous storage should be between 60 and 90 degree F. Keep from freezing

SURFACE PREPARATION

: Preparation methods may vary depending on the system being applied. For a complete system thickness that is higher than 10 mils dry, a fine brush blast (shot blast), is recommended. To assure a trouble free bond, all dust, oil, dirt, foreign contaminants and laitance must be removed. It is recommended to perform a moisture test to determine that the concrete has an appropriate vapor barrier. This can be done by placing a 4’X4’ plastic sheet on the substrate and taping down the edges. Once 24 hours has passed, and the substrate is still dry below the plastic sheet, then the substrate does not show signs of eventual hydrostatic pressure problems that may later cause disbonding. This test does not guarantee, however, that there may not be future hydrostatic pressure issues in the future.

PRODUCT MIXING

: This product has a two to one mix ratio by volume-merely mix 2 gallons of part A with 1 gallon of part B. After the two parts are combined, mix well with slow speed mixing equipment until the material is thoroughly mixed and streak free. Avoid whipping air into the coating. Improper mixing may result in product failure. When pigmenting the product (ex. making a 3 gallon batch), pour 1 gallon of Part B into a measuring/mixing bucket, then add the desired amount of pigment into the Part B and mix until blended. Then add the part A up to the 3 gallon mark and mix and blend very well until material is thoroughly mixed and streak free.

Improper mixing may result in product failure. For best mixing results and proper blending of parts A and B, recommend a Jiffy Mixer style drill mixer.

PRODUCT APPLICATION

: This product can be applied using a flat, knotched, or serrated squeegee, then back rolled to maintain appropriate thickness. Use a ¾” nap roller to back roll the product, and a chip brush to cut out with. Maintain temperatures within the recommended ranges during the application and curing process. It is best to maintain a wet edge to avoid roller marks. Direct sunlight or high temperatures may cause visible roller making during application.

RECOAT OR TOPCOATING:

Installing multiple coats of this product is acceptable. If recoating this product, be sure that all of the solvents have evaporated from the coating during the curing process. Refer to the cure schedule as a guideline to follow, however it is best to test the coating before recoating or topcoating. This is done by pressing your thumb on the coating to ensure a fingerprint impression is not visible. If there is no impression visible, then coating the floor can be done. Note, colder temperatures require longer cure times before product can be recoated. Prior to coating the floor, make sure there are no contaminants exist. If contaminants or a blush exists, remove with a standard detergent cleaner and ensure floor is clean and dry prior to coating. When recoating this product with subsequent coats of urethane, make sure to apply the recoat within the 24 hour time frame. It is recommended to degloss the previous floor prior to coating to ensure a trouble free bond.

CLEANUP/FLOOR CLEANING

:Use solvents for cleanup. When cleaning the floor, CAUTION! Some cleaners may affect the color of the installed floor. Test each cleaner used in a small area, ensuring no damage occurs. Restrict the use of the floor to light traffic and non-harsh chemicals until the floor is fully cured, refer to the cure schedule. Allow the floor to remain completely dry during the curing process.

RESTRICTIONS

: Restrict the use of the floor to light traffic and non-harsh chemicals until the coating is fully cured (see technical data under full cure). It is best to let the floor remain dry for the full cure cycle. Dependent on actual complete system application, surface may be slippery, especially when wet or contaminated; keep surface clean and dry.

LIMITATIONS:

Colors or gloss may be affected by high humidity, low temperatures, chemical exposure, or exposure to lighting such as sodium vapor lights.

For best results use a 3/4” nap roller

Slab on grade requires moisture barrier

Substrate temperature must be 5°F above dew point

All new concrete must be cured for at least 30 days

Physical properties are typical values and not specifications

Tire contact may cause staining or discoloration (long term parked vehicles)

Colors may vary from batch to batch, therefore use only product from the same batch for an entire job.

NOTICE TO BUYER: DISCLAIMER OF WARRANTIES AND LIMITATIONS ON OUR LIABILITY

Floorguard Products® warrants that our products are manufactured to strict quality assurance specifications and that the information supplied by us is accurate to the best of our knowledge. Such information supplied about our products is not a representation or a warranty. It is supplied on the condition that you shall make your own tests to determine suitability of our product for your particular purpose. Listed physical properties are typical and should not be construed as specifications. NO WARRANTY IS MADE, EXPRESSED OR IMPLIED, REGARDING SUCH OTHER IFNORMATION, THE DATA ON WHICH IT IS BASED, OR THE RESULTS YOU WILL OBTAIN FROM ITS USE. NO WARRANTY IS MADE, EXPRESSED OR IMPLIED, THAT OUR PRODUCT SHALL BE MERCHANTABLE OR THAT OUR PRODUCT SHALL BE FIT FOR ANY PARTICULAR PURPOSE. NO WARRANTY IS MADE THAT THE USE OF SUCH INFORMATION OR OUR PRODUCT WILL NOT INFRINGE UPON ANY PATENT. We shall have no liability for incidental or consequential damages, direct or indirect. Our liability is limited to the net selling price of our product or the replacement of our product, at our option. Acceptance of delivery of our product means that you have accepted the terms of this warranty whether or not purchase orders or other documents state terms that vary from this warranty. No representative is authorized to make any representation or warranty or assume any other liability on our behalf with any sale of our products. Our products contain chemicals that may CAUSE SERIOUS PHYSICAL INJURY. BEFORE USING, READ THE MATERIAL SAFETY DATA SHEET AND FOLLOW ALL PRECAUTIONS TO PREVENT BODILY HARM.

Size

Price

PART A ONLY (1 GALLON)

$

107.75

PART B ONLY (1 GALLON)

$

113.41

3 Gallon Kit

$

283.54

1.5 Quart Trial Kit Size

$

55.18

15 Gallon Kit

$

1,247.62

Shipping

Shipping cost:

No cost shipping lower 48 US States FedEx Ground

Delivery time:

Delivery 1 to 5 days after shipment depending on location

Payment

We accept the following payment methods:

PayPal payment due at time of order placement

Please contact us if you have any questions.

Service

PLEASE CONTACT CUSTOMER SERVICE FOR QUESTIONS